The Joint Centre of Advanced Materials (BU-NEU JRCAM) was established by Bournemouth University (BU) and Northeastern University (NEU) in China in 2019. The centre supports high-quality research and education in the field of advanced materials, allowing the two institutions to build strong links in developing novel materials and detailed micro and nano characterisation.

Research activities range from blue-sky research to the translation of results into industrial processes, with a focus on creating new materials that can have large scale applications in manufacturing, healthcare and consumer products.

The centre has four unique research themes: energy materials, healthcare materials, 2D materials technology, and materials for sustainable applications.

The centre was launched by the Vice-Chancellor of Bournemouth University and the Northeastern University President in Shenyang, China, in 2019. The Bournemouth branch of the centre is based at the Advanced Materials Lab at BU, led by Dr Amor Abdelkader, which houses state-of-the-art equipment to enable advanced materials research. In Shenyang, the centre is based in the Energy and Environmental Materials Research Centre (E2MC), led by Professor Ali Kamali.

Research themes

Energy Materials

Wearable Device Materials

Materials for sustainable applications

Graphene and other 2D Materials

Current projects

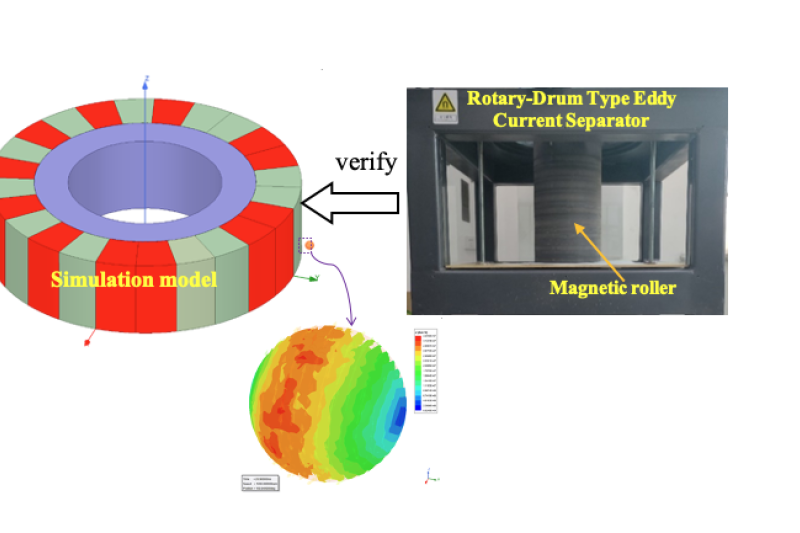

Eddy current separation

Applying electric current to materials can help to refine them, separating out metals and minerals and other useful elements that can be re-used. This can save resources and energy and reduce environmental pollution. The process is large capacity, has a low operating cost, and creates no secondary pollution and has been widely used across a range of waste, including household waste, electrical scrap and foundry sand.

This project mainly focuses on the electrodynamic process in eddy current separation, using simulation and physical experiences to understand the mechanisms affecting the separation and improve the separation effect. Improving the efficiency of the eddy separation process can create substantial economic and environmental benefits due to its wide application.

Project team: Bin Cao, Dr Diogo Montalvao, Dr Amor Abdelkader, Professor Ali Kamali

Graphene-reinforced aluminium nanocomposites

Graphene has shown advantages over other nanomaterials as a reinforcement filler for metallic matrix composites. The project aims to develop the next generation metallic matrix composites by taking graphene-aluminium nanocomposites as an example. We aim to develop new materials with high strength and high conductivity that can replace the conventional aluminium alloys in several aerospace, electronics, and electric power applications.

Project team: Dr Yi Huang, Dr Amor Abdelkader, Professor Ali Kamali

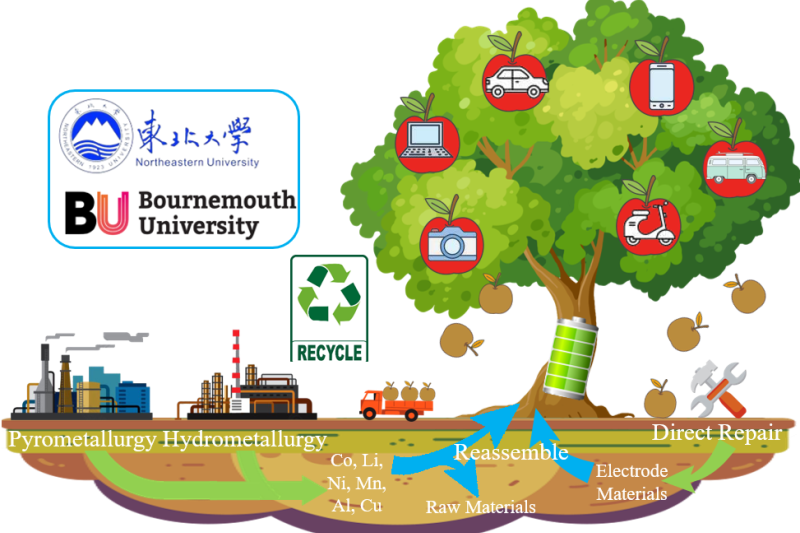

Recycling Lithium-ion batteries

Lithium-ion batteries (LIBs) are extensively used for portable electronic devices and electric vehicles due to their outstanding electrochemical performance. However, spent LIBs have become a massive global burden in terms of waste, with a recycling rate of less than 5%. This can cause serious side effects such as resource scarcity, environmental pollution, safety problems, and increased cost.

This project focuses on developing efficient, green, low-cost and short-process recycling methods for spent LIBs - looking at the direct repair method and closed-loop recycling of spent LIBs.

Project team: Lingyu Kong, Dr Amor Abdelkader, Professor Ali Kamali

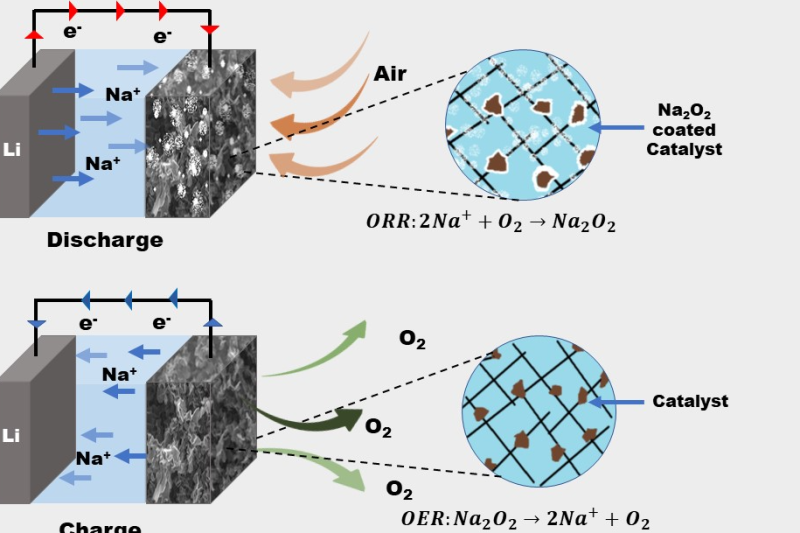

Rechargeable Na-Air batteries with multicomponent cathodes

There is an increasing interest in lithium-air batteries as a potential energy source for powering electric vehicles due to their high theoretical energy density, which approaches that of gasoline. Unfortunately, the currently available rechargeable lithium-air batteries face several challenges, such as poor cyclability and low energy efficiency.

The project looks at designing a new class of electrocatalysts that can enhance the rate of both oxygen reduction reaction (ORR), and oxygen evolution reactions for lithium-air battery cathode. The project focuses on developing new fabrication methods and helping to understand the performance of the batteries.

Project team: Shadeepa Karunarathne, Dr Amor Abdelkader, Professor Ali Kamali

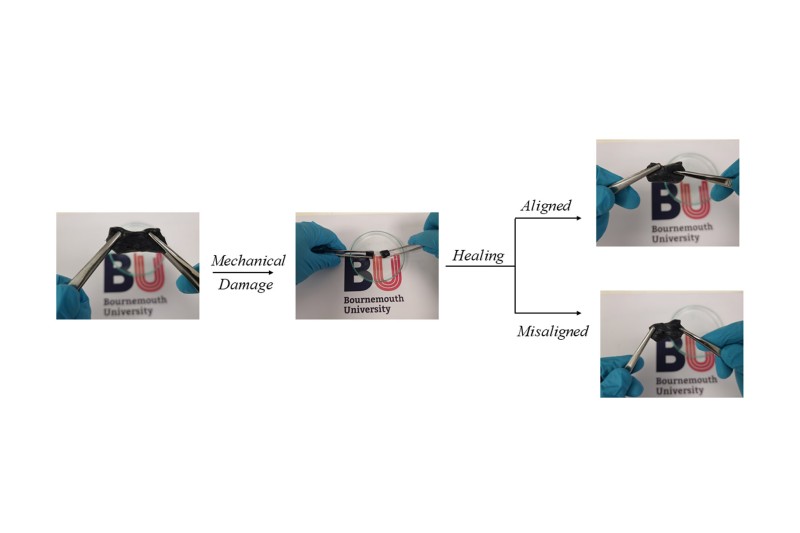

Self-healing polymer composites with graphene and carbon nanotubes

Plastic waste management is a critical environmental concern and a good means of tackling plastic waste is to reduce plastic material failures. This can also help in improving safety aspects around their use, as well as their sustainability. One strategy to extend the life of materials is to make synthetic materials self-heal after they have been damaged, mimicking biological processes and systems.

This multidisciplinary project aims to develop a new class of nanocomposite materials with self-healing ability, which are able to perceive and repair the damage using fundamental tools of nanotechnology.

Project team: Chirag Ratwani, Professor Mark Hadfield, Dr Amor Abdelkader, Professor Ali Kamali

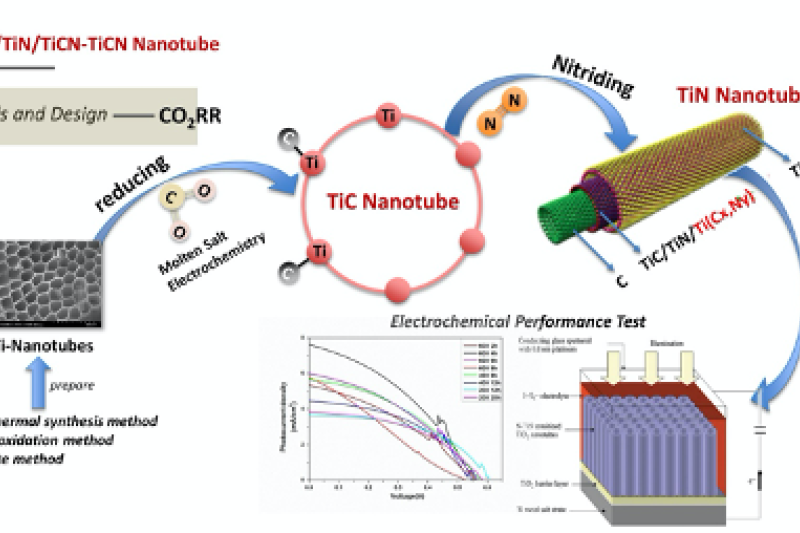

Preparation of TiC nanotubes via electrochemical capture and conversion of CO2 in high-temperature molten salt

Capturing and converting carbon dioxide (CO2) can help to remove it from the atmosphere and enable it to be re-used in other processes.

This project is exploring the capture of CO2 by high-temperature molten salt electrochemistry, reducing it to amorphous carbon at the cathode of a titanium sheet covered with a layer of TiO2 nanotubes.

Project team: Hanlin Song, Dr Ben Thomas, Dr Amor Abdelkader, Professor Ali Kamali

A diagram of the eddy current separation process

A diagram of the eddy current separation process  Recycling Lithium-ion batteries

Recycling Lithium-ion batteries Schematic diagram of an aprotic Na-air battery

Schematic diagram of an aprotic Na-air battery Autonomous self-healing in flexible polymer nanocomposite

Autonomous self-healing in flexible polymer nanocomposite A diagram of the carbon capture process

A diagram of the carbon capture process